Closed Loop Liquid Cooling (CLC)

By: Saar Blitz

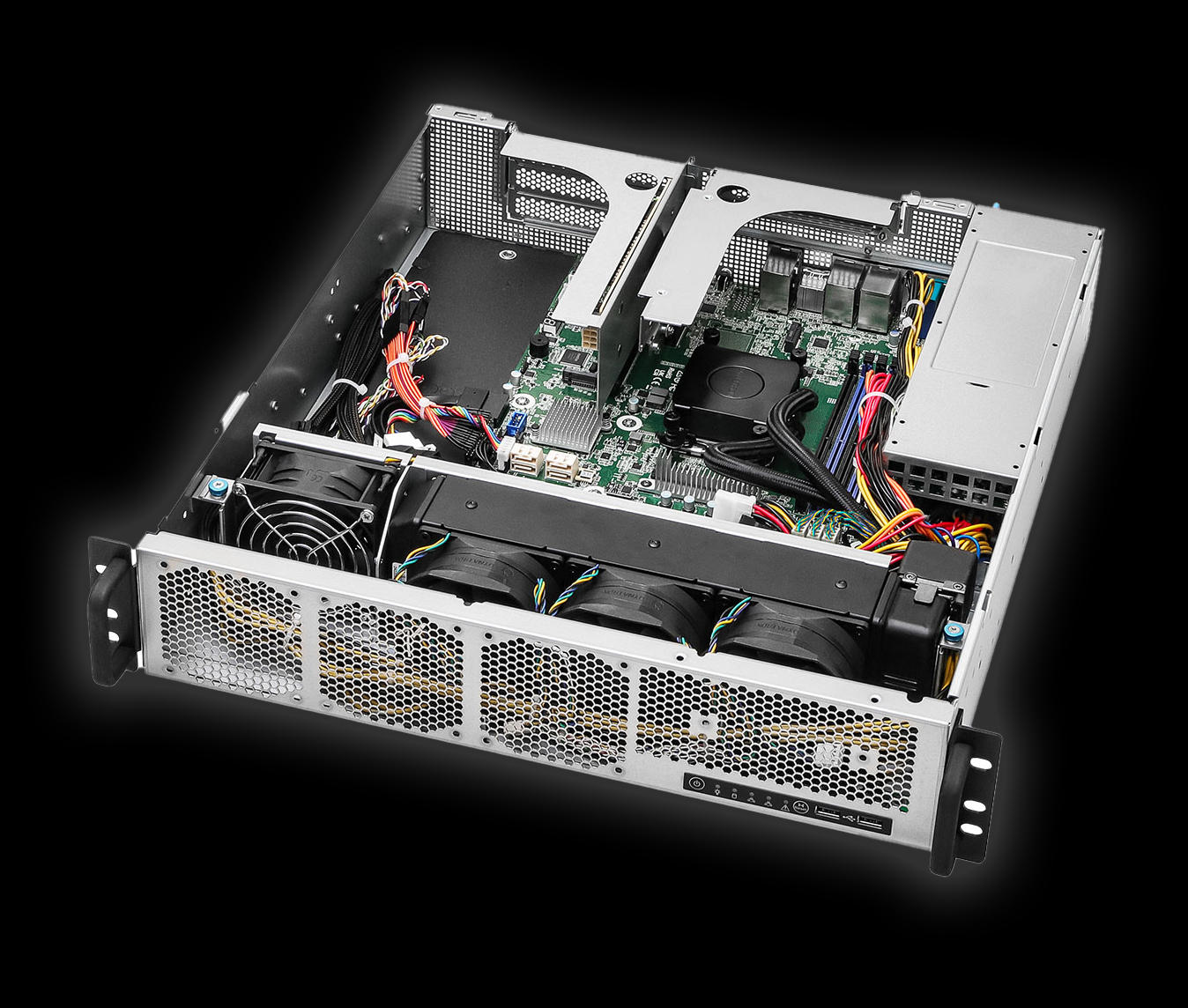

In an era when advanced technologies such as Artificial Intelligence (AI), machine learning, industrial simulations, and high-performance computing place unprecedented demands on computing systems, cooling has become a central challenge in the design of modern infrastructure. Technology companies developing compute-based software products across industries such as cybersecurity, medical devices, defense, and semiconductors must now adapt to this new reality and decide whether to replace traditional air-cooling systems, which often cannot handle the high computational density and energy consumption of AI-optimized components, with Closed-loop Liquid Cooling (CLC) systems.

The rise of CLC adoption stems from its role as the optimal solution for heat management in knowledge-intensive systems. This trend is particularly evident among industrial organizations using computing in production lines and control systems, where reliability and resilience to high external temperatures are critical.

Today, it has become clear that cooling is one of the most pressing issues developers face. They must select not only the right computer for their application but also a cooling solution that ensures system stability and performance over time.

Before liquid cooling became a central component in industrial computing and data centers, air cooling was the dominant method. Air cooling remains widely used in many systems due to its simplicity and low cost. However, it has significant limitations in heat dissipation. As processors have become denser and more powerful over the years, air cooling is no longer sufficient. Moreover, air cooling generates significant noise, consumes more energy, and struggles under extreme workloads, making it less effective. As heat loads increased, especially with high-power GPUs like the NVIDIA H100 and AMD EPYC processors, air cooling could no longer cope, underscoring the need for CLC, which offers a more efficient heat-management solution.

Key advantages of CLC for servers include:

- More efficient heat dissipation: Liquid with high thermal conductivity absorbs and transfers heat rapidly from the CPU and GPU to the radiator. This efficiency is critical for servers with high computational loads

- Improved performance and stability: Servers operating at lower temperatures are more stable and can maintain higher operating frequencies over time. Consequently, liquid-cooled systems operate more quietly, as fans require less effort. Stable temperatures also reduce wear and extend the lifespan of electronic components – an essential advantage for the long-term operation of critical systems

These benefits directly address the challenges in industrial computing environments:

- Handling powerful processors in compact enclosures: Modern industrial computers often require high processing power in small, fanless enclosures, as in AI and computer vision applications. Liquid cooling is sometimes the only solution that allows integration of high-performance processors while maintaining effective heat dissipation.

- Durability in harsh environments: Industrial computers often operate in dusty, humid, vibrating, or extreme-temperature environments. CLC systems are fully sealed, preventing dust and contaminants from entering.

- Compactness and installation flexibility: When high processing power is needed in small, fanless enclosures, the radiator can be located separately from the processing unit, enabling smaller, sealed enclosures suitable for space-constrained locations.

- Reliability and continuous operation: In factories and production lines, any downtime is costly. The high reliability of liquid cooling, which maintains low and stable temperatures even under constant load, ensures smooth operation and prevents overheating-related failures.

CLC systems are applied across a variety of industrial environments including maritime applications requiring fully sealed, compact, and extremely quiet systems; manufacturing facilities benefiting from solutions that handle hot and dusty conditions while reducing downtime; in the energy sector where ASIC chip and wind turbine cooling demands reliability and long lifespans; and in communications where ruggedized liquid-cooled systems can be deployed in outdoor and desert environments. Broadly, liquid cooling serves as a bridge between data centers and the production floor and is an essential component of Industry 4.0 implementation.

Ultimately, investing in liquid cooling systems is not merely a technical consideration but a strategic decision with direct impact on competitive advantage, product reliability, and cost efficiency. Choosing the right solution and an experienced technology partner to guide the process ensures that products achieve not only durability and performance but also optimal user experience and peace of mind for end customers.

Saar Blitz is CVP of Technology at HIPER Global

**The article was published at the “People and Computers” magazine, on October 27, 2025